PRODUCT CODE 42-58

Conductive Elastomers

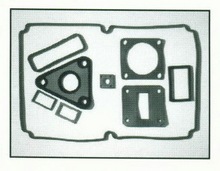

Effective Shielding Co. provides a wide selection of conductive elastomers to ensure a successful galvanic compatibility with any emi gasket. Conductive elastomers are composed of fine micro particles that are compounded into a high-grade silicone or EPDM, providing excellent EMI/RFI shielding and an environmental seal for all applications. Elastomers ensure that electronic components within connected applications are compatible, as well as preventing resistance between joined surfaces.

To choose the appropriate conductive elastomer for your emi gasket, you will need to evaluate what type of environment the application will be used in. If there is little to no risk of environmental threat, such as water or dust, we recommend you choose from our nickel coated graphite options. These materials are less expensive and extremely resilient when used in controlled surroundings.

If your application encounters numerous environmental threats, you should consider selecting from our Silver Plated elastomers. Through many proven tests, silver has demonstrated to be one of the most robust and long-lasting metals, standing up to nearly every imaginable environmental threat.

All emi gasket materials are available in molded sheets, strips, die cut, or extruded forms.

To order, please email your specifications to sales@effshield.com or call us at 610-429-9449

| Material Types: | Product Code: | MIL-DTL-83528 |

| Pure Silver in Silicone Medium Durometer | 42-XXXX-XXXX | Type E |

| Carbon in Silicone | 43-XXXX-XXXX | N/A |

| Pure Silver in Fluoro Silicone | 44-XXXX-XXXX | Type F |

| Silver Plated Copper in Silicone High Durometer | 45-XXXX-XXXX | Type K |

| Nickel Coated Graphite in Silicone | 46-XXXX-XXXX | N/A |

| Nickel Coated Graphite in EPDM | 47-XXXX-XXXX | N/A |

| Silver Plated Nickel in EPDM | 48-XXXX-XXXX | N/A |

| Pure Silver in Silicone High Durometer | 49-XXXX-XXXX | Type H |

| Silver Plated Aluminum in Fluoro Silicone | 50-XXXX-XXXX | Type D |

| Silver Plated Nickel in Silicone | 51-XXXX-XXXX | Type L |

| Silver Plated Glass in Silicone | 52-XXXX-XXXX | Type M |

| Silver Plated Copper in Silicone Reinforced | 53-XXXX-XXXX | Type G |

| Pure Silver in Silicone Low Durometer | 54-XXXX-XXXX | Type J |

| Silver Plated Copper in Silicone | 55-XXXX-XXXX | Type A |

| Silver Plated Copper in Fluoro Silicone | 56-XXXX-XXXX | Type C |

| Silver Plated Aluminum in EPDM | 57-XXXX-XXXX | N/A |

| Silver Plated Aluminum in Silicone | 58-XXXX-XXXX | Type B |

| Custom Gasket or Extrusion | XX-1015-TBD | as required |

| Specifications: | ||||||||

| Product Code | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 |

| Operated Temp (C) Min. Max |

-55 +160 |

-55 +200 |

-65 +160 |

-45 +125 |

-55 +200 |

-30 +100 |

-40 +120 |

-55 +180 |

| Specific Gravity +/- 13% | 3.5 | 1.20 | 4.0 | 3.5 | 3.05 | 2.1 | 3.70 | 4.0 |

| Hardness Shore A | 65 | 70 | 75 | 85 | 70 | 75 | 80 | 80 |

| Compression Deflection % Min. | 2.5 | 3.5 | 3.5 | 2.5 | 3.5 | 2.0 | 3.0 | 2.5 |

| Tensile Strength #/in. sq. | 300 | 450 | 250 | 400 | 150 | 200 | 200 | 400 |

| Elongation % Min. Max. |

200 500 |

—- 160 |

100 300 |

100 300 |

—- 300 |

75 —- |

100 350 |

90 290 |

| Compression Set % | 45 | 30 | 60 | 35 | 35 | 2.0 | 40 | 60 |

| Tear Strength Pounds Per Inch Min. | 50 | 15 | 40 | 40 | 40 | 70 | 60 | 60 |

| Volume Resistivity (Ohm-Cm as Received) | 002 | 6-8 | .002 | .005 | .100 | 5 | .010 | .005 |

| Product Code | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 |

| Operated Temp (C) Min. Max |

-55 +160 |

-55 +125 |

-55 +200 |

-45 +125 |

-55 +160 |

-55 +125 |

-55 125 |

-45 +160 |

-55 +160 |

| Specific Gravity +/- 13% | 2.0 | 4.0 | 1.8 | 4.75 | 1.7 | 3.5 | 4.0 | 2.30 | 2.0 |

| Hardness Shore A | 70 | 75 | 65 | 80 | 45 | 65 | 75 | 60 | 65 |

| Compression Deflection % Min. | 3.5 | 3.5 | 3.5 | 2.5 | 8.0 | 3.5 | 3.5 | 8 | 3.5 |

| Tensile Strength #/in. sq. | 180 | 200 | 200 | 600 | 150 | 200 | 180 | 150 | 200 |

| Elongation % Min. Max. |

60 260 |

100 300 |

100 280 |

20 N/A |

50 250 |

100 300 |

100 300 |

50 200 |

100 300 |

| Compression Set % | 30 | 32 | 30 | N/A | 35 | 32 | 35 | 30 | 32 |

| Tear Strength Pounds Per Inch Min. | 35 | 30 | 30 | 70 | 20 | 25 | 35 | 80 | 30 |

| Volume Resistivity (Ohm-Cm as Received) | .012 | .005 | .006 | .007 | .010 | .004 | .010 | .020 | .008 |

|

“P” Shaped Extrusion |

||||

|

||||

| Part Number | A | B | C | D |

| XX-4298-0031 | .200″ | .081″ | .275″ | .062″ |

| XX-4298-0032 | .200″ | .081″ | .650″ | .062″ |

| XX-4298-0033 | .250″ | .125″ | .250″ | .062″ |

| XX-4298-0034 | .250″ | .125″ | .375″ | .062″ |

| XX-4298-0035 | .250″ | .151″ | .625″ | .062″ |

|

Solid Round Extrusion |

|

|

|

| Part Number | Dia. |

| XX-4298-0001 | .053″ |

| XX-4298-0002 | .062″ |

| XX-4298-0003 | .070″ |

| XX-4298-0004 | .093″ |

| XX-4298-0005 | .103″ |

| XX-4298-0006 | .119″ |

| XX-4298-0007 | .125″ |

| XX-4298-0008 | .139″ |

| XX-4298-0009 | .216″ |

| XX-4298-0010 | .250″ |

|

Hollow Round Extrusion |

||

|

||

| Part Number | I.D. | O.D. |

| XX-4298-0011 | .040″ | .125″ |

| XX-4298-0012 | .045″ | .125″ |

| XX-4298-0013 | .050″ | .156″ |

| XX-4298-0014 | .125″ | .250″ |

| XX-4298-0015 | .192″ | .312″ |

| XX-4298-0016 | .250″ | .375″ |

| XX-4298-0017 | .250″ | .437″ |

| XX-4298-0018 | .312″ | .437″ |

|

Rectangular Extrusion |

||

|

||

| Part Number | Thickness | Width |

| XX-4298-0019 | .042″ | .063″ |

| XX-4298-0020 | .062″ | .093″ |

| XX-4298-0021 | .075″ | .125″ |

| XX-4298-0022 | .062″ | .125″ |

| XX-4298-0023 | .062″ | .156″ |

| XX-4298-0024 | .062″ | .250″ |

| XX-4298-0025 | .075″ | .500″ |

| XX-4298-0026 | .125″ | .500″ |

| XX-4298-0027 | .188″ | .500″ |

| XX-4298-0028 | .062″ | .750″ |

| XX-4298-0029 | .062″ | .880″ |

| XX-4298-0030 | .250″ | 1.00″ |

| Sheet Form | |||

| Thickness | 12″ X 12″ | 12″ X 18″ | 15″ X 20″ |

| .020″ | XX-3817-0001 | XX-3817-0006 | XX-3817-0011 |

| .032″ | XX-3817-0002 | XX-3817-0007 | XX-3817-0012 |

| .062″ | XX-3817-0003 | XX-3817-0008 | XX-3817-0013 |

| .093″ | XX-3817-0004 | XX-3817-0009 | XX-3817-0014 |

| .125″ | XX-3817-0005 | XX-3817-0010 | XX-3817-0015 |

Our Products

Commercial Products

Filled or Unfilled Metals

Wire Oriented in Silicone

Springshield

Wire Mesh Bonded to Elastomer

Knitted Wire Mesh

Air Ventilation Panels

Conductive Adhesives

Conductive Elastomers